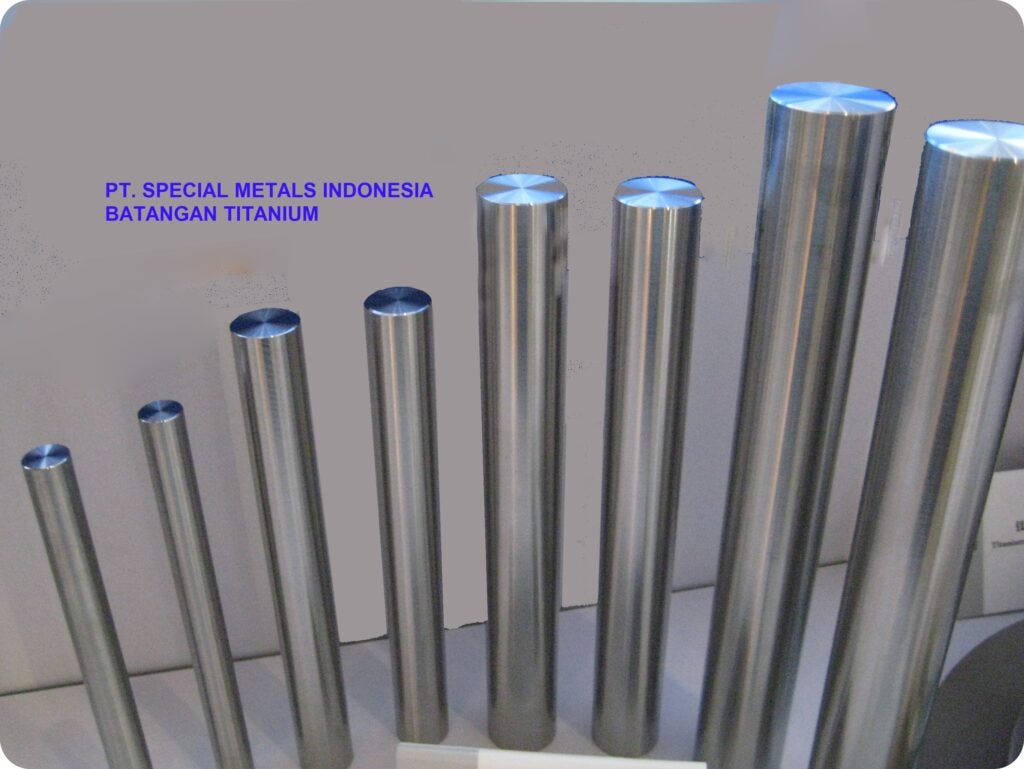

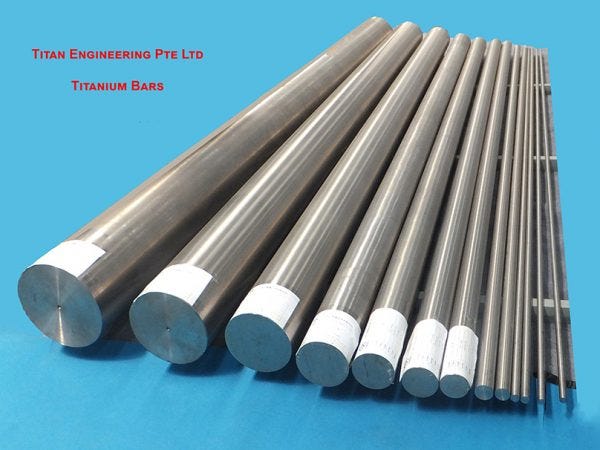

Titanium batangan, or titanium bars, are known for their incredible strength, light weight, and exceptional resistance to corrosion. These properties make them an ideal choice for a variety of industries, from aerospace and medical to marine and chemical processing. In this article, we will explore the numerous benefits of using titanium batangan, and why it’s a valuable material for many applications. We will also touch on related products like pipa titanium (titanium pipes) and discuss the harga titanium batangan (price of titanium bars).

Exceptional Strength and Durability

High Strength-to-Weight Ratio

One of the most remarkable benefits of titanium batangan is its high strength-to-weight ratio. Titanium is as strong as steel but 45% lighter, making it an excellent choice for applications where weight reduction is crucial without compromising strength. This characteristic is especially valuable in the aerospace and automotive industries, where reducing weight can significantly enhance fuel efficiency and performance.

Superior Corrosion Resistance

Titanium batangan is renowned for its superior resistance to corrosion. Unlike other metals, titanium does not rust or corrode when exposed to saltwater, chlorine, and other harsh chemicals. This makes it an ideal material for marine environments, chemical processing plants, and even medical implants. Pipa titanium, for instance, is commonly used in chemical processing and desalination plants due to its ability to withstand highly corrosive conditions.

Versatility in Applications

Aerospace Industry

In the aerospace industry, titanium batangan is used extensively due to its light weight and high strength. Aircraft components such as landing gear, exhaust ducts, and structural parts are often made from titanium to reduce weight and improve fuel efficiency. Additionally, titanium’s ability to withstand extreme temperatures makes it suitable for jet engines and other high-heat applications.

Medical Field

Titanium is biocompatible, meaning it is non-toxic and not rejected by the human body. This property makes titanium batangan a popular choice for medical implants, including joint replacements, dental implants, and surgical instruments. The material’s strength and resistance to corrosion ensure that these medical devices have a long lifespan and do not degrade over time.

Chemical Processing

In the chemical processing industry, titanium batangan and pipa titanium are used in equipment that handles highly corrosive substances. Titanium’s resistance to chemicals like chlorine and sulfuric acid means that it can be used in heat exchangers, reactors, and storage tanks, providing a long-lasting and maintenance-free solution.

Cost-Effectiveness

Longevity and Durability

Although the initial harga titanium batangan may be higher compared to other metals, its longevity and durability make it a cost-effective choice in the long run. Titanium’s resistance to corrosion and wear reduces the need for frequent replacements and maintenance, leading to significant cost savings over time. This makes it a smart investment for industries that require durable and long-lasting materials.

Energy Savings

The use of titanium batangan in industries like aerospace and automotive can lead to significant energy savings. The material’s light weight helps reduce fuel consumption, leading to lower operational costs and a smaller carbon footprint. This is particularly important in today’s world, where there is a growing emphasis on sustainability and environmental responsibility.

Environmental Benefits

Recyclability

Titanium is highly recyclable, and the process of recycling titanium requires less energy compared to extracting and processing new titanium. This makes it an environmentally friendly choice for industries looking to reduce their environmental impact. Recycled titanium retains the same properties as new titanium, ensuring that it remains a high-performance material.

Reduced Environmental Impact

The use of titanium batangan in various applications helps reduce the overall environmental impact. For example, in the aerospace industry, the reduction in weight leads to lower fuel consumption and reduced greenhouse gas emissions. In the medical field, titanium implants last longer and do not require frequent replacements, reducing medical waste.

Technological Advancements

3D Printing

The advent of 3D printing technology has opened up new possibilities for the use of titanium batangan. Titanium powder can be used in additive manufacturing to create complex and customized parts that are difficult to produce using traditional manufacturing methods. This technology is particularly useful in the aerospace and medical industries, where precision and customization are crucial.

Innovative Applications

Researchers and engineers are continually finding new and innovative applications for titanium batangan. For example, titanium is being used in the construction of high-performance sports equipment, such as bicycles and golf clubs, due to its light weight and strength. Additionally, the material is being explored for use in sustainable architecture and renewable energy solutions, such as wind turbines and solar panels.

Enhanced Performance

High Temperature Resistance

Titanium batangan can withstand extreme temperatures without losing its strength or becoming brittle. This makes it an ideal material for applications that involve high heat, such as jet engines, gas turbines, and automotive exhaust systems. The material’s high temperature resistance ensures that it performs reliably under demanding conditions.

Low Thermal Expansion

Titanium has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. This property is crucial in applications where dimensional stability is important, such as in aerospace and precision engineering. Pipa titanium, for example, is used in heat exchangers because it maintains its shape and performance under varying thermal conditions.

Availability and Supply Chain

Global Availability

Titanium batangan is widely available from suppliers around the world. The global titanium supply chain ensures that industries have access to high-quality titanium products, including bars, pipes, and sheets. Companies that jual titanium batangan (sell titanium bars) offer a range of grades and sizes to meet the specific needs of different applications.

Consistent Quality

Reputable suppliers of titanium batangan adhere to strict quality control standards to ensure that the material meets the required specifications. This consistency in quality is essential for industries that rely on titanium for critical applications, such as aerospace, medical, and chemical processing. The availability of certified titanium products helps maintain the integrity and performance of end-use applications.

Conclusion

The benefits of using titanium batangan are numerous and far-reaching. From its exceptional strength and durability to its versatility in various applications, titanium is a valuable material that offers long-term cost savings and environmental benefits. Whether in the form of pipa titanium for chemical processing or titanium implants in the medical field, the material’s unique properties make it an indispensable choice for many industries.

- As technological advancements continue to unlock new possibilities, the demand for titanium batangan is expected to grow. Companies that jual titanium batangan play a crucial role in meeting this demand by providing high-quality titanium products that meet the stringent requirements of different industries. Despite the higher initial harga titanium batangan, the long-term benefits and cost savings make it a wise investment for those looking for a durable, reliable, and sustainable material.