According to TechSci report on, “India Ammonium Nitrate Market – By Region, Competition Forecast & Opportunities, 2027”, the market growth can be attributed to increasing civil construction activities across the country. Moreover, the rapidly changing food consumption habits and consumer preferences due to urban lifestyles and the rise in disposable income are adding to the demand for nutritive agricultural food products. In addition, the surging population of India is creating huge pressure on the agricultural sector to increase crop yield. Additionally, the growing population has also resulted in increased demand for residential buildings, particularly in metropolitan cities. Therefore, both government and private sectors are investing in the construction and development of residential infrastructure. Ammonium nitrate is the main component used for commercial explosives, which is widely used in mining and civil construction activities. Moreover, the mining industry utilizes ammonium nitrate in industrial-grade explosives manufacturing. Ammonium Nitrate Fuel Oil is one of the economical blasting agents which is utilized for dry hole blasting operations. The flourishing oil & gas exploration activities across India is expected to augment the ammonium nitrate market growth in the coming years.

Browse over XX market data Figures spread through 70 Pages and an in-depth TOC on “India Ammonium Nitrate Market” – https://www.techsciresearch.com/report/india-ammonium-nitrate-market/12795.html

Market Overview

As of 2023, the India ammonium nitrate market is valued at approximately USD 1.5 billion and is expected to grow at a CAGR of 6.5% from 2024 to 2029. This growth is fueled by the rising demand for fertilizers in agriculture and the expansion of infrastructure and mining activities.

Key Drivers

1. Agricultural Demand

- Increasing Population: With the growing population, there is a rising demand for food, necessitating higher agricultural productivity. Ammonium nitrate, as a high-efficiency nitrogenous fertilizer, plays a crucial role in enhancing crop yields.

- Government Initiatives: The Indian government’s initiatives to support farmers through subsidies and the promotion of efficient fertilizers are boosting the demand for ammonium nitrate in agriculture.

2. Industrial Applications

- Mining and Quarrying: The booming mining sector, driven by the demand for minerals and metals, is a significant consumer of ammonium nitrate. It is used extensively in explosives for mining operations.

- Construction Sector: Infrastructure development projects, such as roads, bridges, and buildings, also utilize ammonium nitrate in explosives for blasting purposes.

3. Technological Advancements

- Innovations in Production: Technological advancements in the production processes of ammonium nitrate are improving efficiency and reducing costs, making it more accessible for various applications.

Market Segmentation

By Type

- High-Density Ammonium Nitrate (HDAN)

- Low-Density Ammonium Nitrate (LDAN)

- Ammonium Nitrate Solution

By Application

- Fertilizers

- Explosives

- Others (pharmaceuticals, chemicals, etc.)

By Region

- North India

- South India

- East India

- West India

Competitive Landscape

The ammonium nitrate market in India is competitive, with several key players focusing on expanding their production capacities and enhancing their market presence through strategic initiatives. Major companies include:

- National Fertilizers Limited

- Rashtriya Chemicals and Fertilizers Limited

- Deepak Fertilisers and Petrochemicals Corporation Limited

- Gujarat Narmada Valley Fertilizers & Chemicals

- Indian Farmers Fertilizer Cooperative Limited (IFFCO)

Recent Trends

1. Sustainable Practices

- There is a growing trend towards sustainable agricultural practices, which includes the use of environmentally friendly and efficient fertilizers like ammonium nitrate.

2. Digital Agriculture

- The integration of digital technologies in agriculture, such as precision farming and smart irrigation systems, is driving the demand for high-efficiency fertilizers.

3. Expansion in Mining Activities

- The government’s focus on self-reliance in minerals and metals is leading to the expansion of mining activities, thereby increasing the demand for ammonium nitrate in explosives.

Challenges

1. Regulatory Constraints

- The production and use of ammonium nitrate are subject to stringent regulations due to its potential misuse in explosives. Ensuring compliance with these regulations is a significant challenge for manufacturers.

2. Environmental Concerns

- The use of ammonium nitrate in agriculture can lead to environmental issues such as soil acidification and water pollution if not managed properly.

3. Market Competition

- The presence of numerous players in the market creates intense competition, requiring continuous innovation and cost management.

Benefits of the Research Report

- Comprehensive Market Insights: Provides detailed analysis of market dynamics, including drivers, restraints, and opportunities.

- In-depth Competitive Analysis: Highlights key players, their market strategies, and competitive positioning.

- Trend Identification: Identifies emerging trends shaping the market, helping businesses stay ahead of the curve.

- Consumer Behavior Analysis: Offers insights into consumer preferences and purchasing behavior, aiding in product development and marketing strategies.

- Market Forecasts: Provides accurate market forecasts, helping stakeholders make informed decisions.

- Investment Opportunities: Highlights potential investment opportunities in the ammonium nitrate market.

- Technological Advancements: Discusses the impact of technological innovations on the market and future prospects.

- Regulatory Framework: Outlines the regulatory environment, helping businesses navigate complex legal requirements.

- Regional Analysis: Detailed analysis of market dynamics across different regions.

- Sustainability Practices: Emphasizes the importance of eco-friendly and sustainable practices in the market.

A list of major market players of the India ammonium nitrate market includes:

- Deepak Fertilizers and Petrochemicals Corporation Limited

- Rashtriya Chemicals & Fertilizers Ltd.

- National Fertilizers Limited

- Gujarat Narmada Valley Fertilizers & Chemicals Company

DOWNLOAD FREE SAMPLE REPORT – https://www.techsciresearch.com/sample-report.aspx?cid=12795

Customers can also request for 10% free customization on this report.

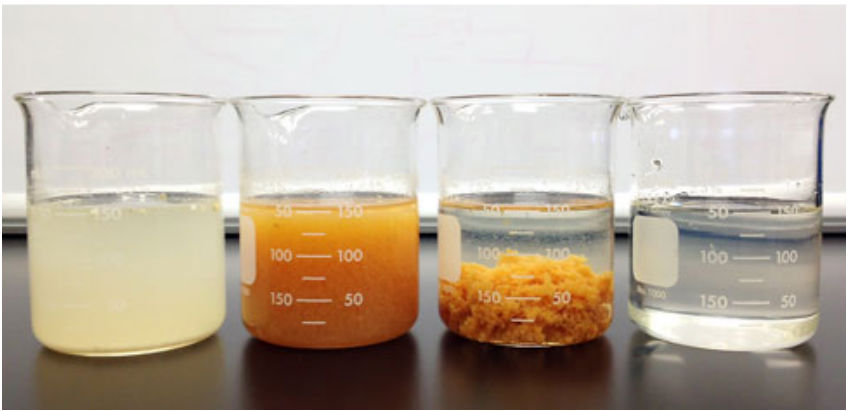

“The India ammonium nitrate market is slightly competitive. This is primarily due to the stringent regulations on the use of ammonium nitrate. Moreover, in India, the number of ammonium nitrate manufacturers and suppliers is limited. The primary companies working in the Indian market are limited, among which Deepak Fertilizers and Gujrat Narmada Valley Fertilizers are the top manufacturers of the product, hence contracting the competition in the market. Besides this, the ongoing advancements and innovations in the product to enhance its effectiveness are also adding to the market growth. For instance, Gujrat Narmada Valley Fertilizers has developed ammonium nitrate liquid fertilizer, and the improved efficacy of this product in field application has been witnessed in the field trials. The new market players are advised to invest in R&D activities to reduce the pollution and generation of waste products while manufacturing the product in order to establish their brand in the market,” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm.

“India Ammonium Nitrate Market By Solids (High Density Ammonium Nitrate v/s Low Density Ammonium Nitrate), By Application (Fertilizers, Explosives, Others), By End User Industry (Agriculture, Mining, Defense, Others), and By Region, Competition Forecast and Opportunities, 2027” has evaluated the future growth potential of India ammonium nitrate market and provides statistics & information on market size, structure and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in India ammonium nitrate market.

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: sales@techsciresearch.com

Website: https://www.techsciresearch.com