Optimizing processes is paramount for efficiency in the dynamic landscape of material handling. One crucial player in this realm is the Bulk Bag Discharger. This hero makes unloading materials easier and has many benefits for different industries. Businesses in Pune are using Bin Activator Pune and Circular Vibratory Screens. These solutions have many advantages. Here are six reasons why using a Bulk Bag Discharger can improve your material handling operations.

1. Increased Operational Efficiency

Lifting and pouring heavy bags by hand wastes worker hours and slows down production. The frames of Bulk Bag Unloaders have an electric hoist. The hoist is mounted on the ceiling. It allows easy lifting of bags up to 2 tons. This helps to avoid back strain.

Swift Bulk Bag Unloaders loading saves time. It creates a smoother material flow. It helps keep up with processing demand. There is no downtime or output lags because of bag handling bottlenecks.

2. Reduced Wastage/Improved Yield

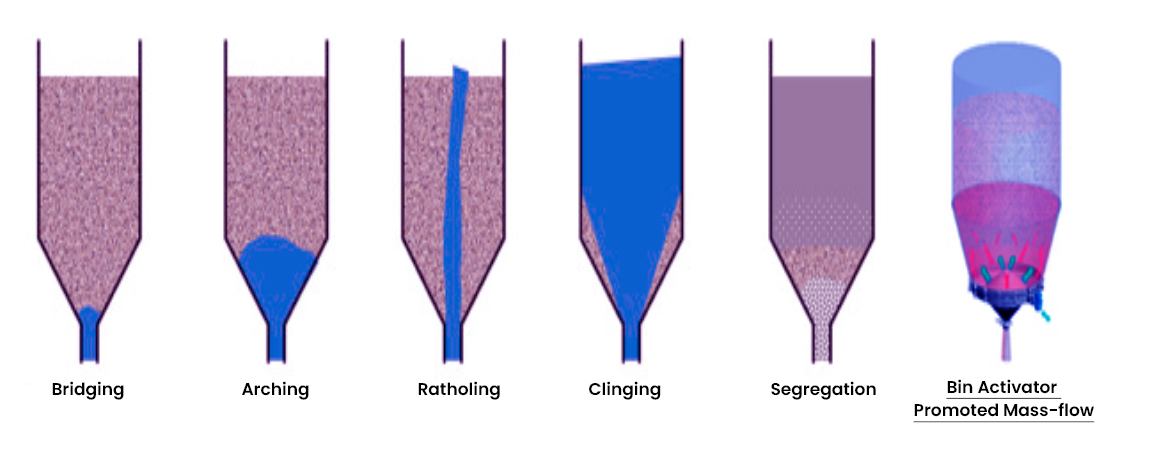

Dumping bulk bags without support causes spills and losses. Dischargers hold bags above vessels. They regulate material discharge with a slide gate.

This material flow prevents spills. It empties bags completely. It uses vibration motors. No product is left inside. Manual draining can leave residue. It yields better and has no waste.

3. Enhanced Operational Safety

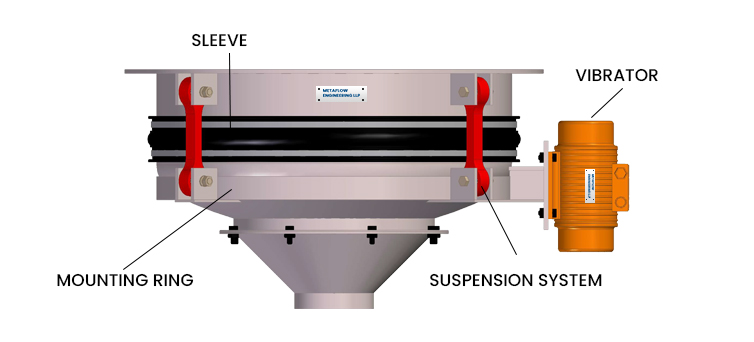

Manually lifting heavy bags brings injury risks from pulls, drops, and trips/falls. However, automated Bulk Bag Unloader Pune removes direct worker contact, optimizing floor safety. State-of-the-art designs even have tear detection systems preventing bag ruptures through sensors detecting abnormal discharge rates.

You also avoid exposure to fine powders as enclosed designs prevent dusting, unlike makeshift cut-open pouring with billowing particle clouds!

4. Customizable Configurations

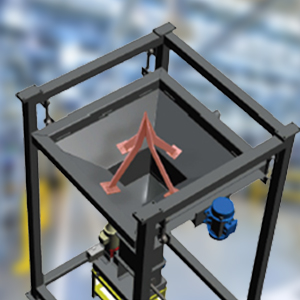

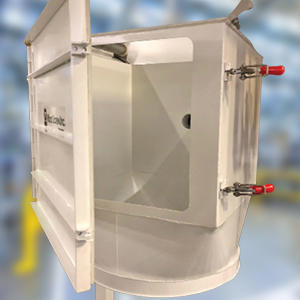

Metaflow Engineering, a leading Bulk Bag Discharger manufacturer, offers customizable frames, bag lifts, hoppers, and de-stuffing modules. These options can be transportable or mezzanine-mounted. This allows for a perfect fit to the facility’s height, the required flow rates, and the feeding positions.

Specific design elements can help with trickier application needs. For example, they can handle high fat content powders that tend to stick.

5. Hygienic Construction

Pharmaceutical and food applications demand the utmost hygienic material handling to avoid batch contamination. Discharger contact parts made from stainless steel or easy-clean plastics cater to such sensitive sectors. Smooth polished surfaces prevent particle accumulation and ease washdowns.

Certain models even have inflatable tube seals ensuring complete dust retention – vital for sterile processes like dairy or biopharma!

6. Validation Assistance

Reputable discharger brands provide documentation. This includes CAD drawings, functional descriptions, and equipment test procedures. The purpose is to support client validation needs. This is especially important in regulated sectors like chemicals and healthcare.

Conclusion

The advantages of integrating a Bulk Bag Discharger in material handling extend far beyond streamlined processes. From the bustling industrial landscape of Pune to global manufacturing hubs, businesses are reaping the benefits of improved efficiency, workplace safety, and cost-effectiveness. As technology continues to evolve, embracing solutions like Bulk Bag Dischargers from Metaflow Engineering becomes a choice and a necessity for those seeking to stay ahead in the competitive material handling world.