Lead or Pb is a bluish-white metal that has a lustrous texture. It is a highly malleable and ductile metal that is a poor conductor of electricity. Its boiling point measures around 1755° C, and its melting point measures around 327° C. Raw Lead is rare but is found naturally in ore with zinc, silver, and copper and is extracted together with these metals. Most of the naturally occurring lead found in the environment is produced from the results of human activities. It harms human health and causes various disorders, such as a rise in blood pressure, kidney and brain damage.

Request for Real-Time Lead Prices: https://procurementresource.com/resource-center/lead-price-trends/pricerequest

The key importer countries are namely United States, India, and Germany. On the contrary, the critical exporting countries are Korea, Germany, and India, in the same order.

Key Details About the Lead Prices Trend:

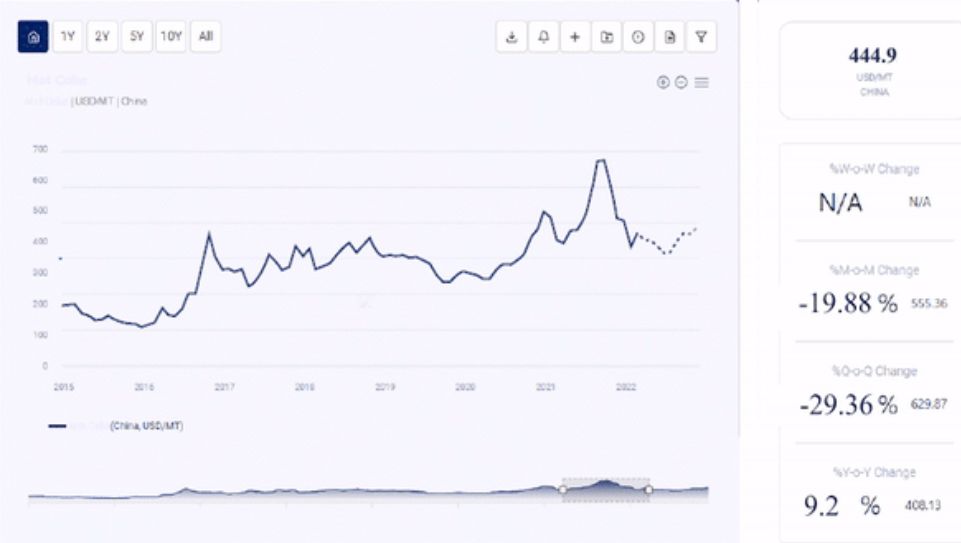

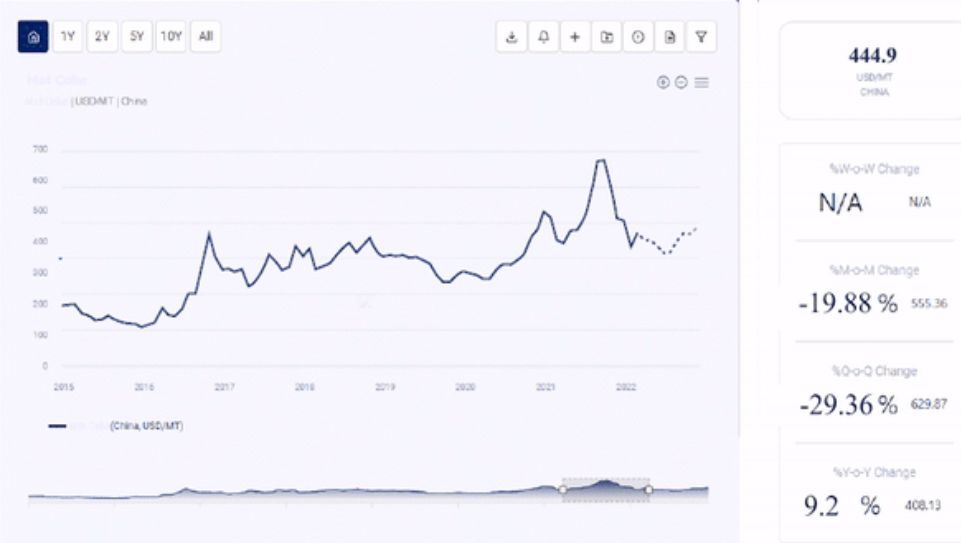

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Lead Prices in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The Lead Prices Trend, including India Lead Prices, USA Lead Prices, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Lead Prices Trend:

The commercial application of Lead includes metal production, the production of paints and pesticides. It is also used in manufacturing pipelines, etc. It is incorporated into various food and beverage items like soft drinks, wines, etc.

The commercial application of Lead includes metal production, the production of paints and pesticides. It is also used in manufacturing pipelines, etc. It is incorporated into various food and beverage items like soft drinks, wines, etc.

Additionally, Lead is primarily used in producing batteries, i.e., Lead- acid batteries, which are used extensively in automobiles and cars. The screens of computers and televisions contain lead as it acts as an effective radiation shield, protecting users from the harmful effects of radiation emitted by the devices. Other uses include incorporation of lead in cables, lead crystal glassware, solders, and weighing equipment etc.

Key Players:

- Umicore N.V

- American Elements

- Glencore plc

- Korea Zinc Co., Ltd.

- The Doe Run Resources Corporation

- Hindustan Zinc Limited

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA