Aluminum extrusion services provide precision solutions for custom needs, offering a versatile and cost-effective way to create complex shapes and designs for a wide range of applications. From architectural features to industrial equipment, aluminum extrusions are used in various industries due to their unique combination of strength, corrosion resistance, and lightweight properties.

The Benefits of Aluminum Extrusion Services

Aluminum extrusion services offer numerous benefits, including the ability to create complex shapes and designs that would be difficult or impossible to produce using other manufacturing methods. This process also allows for the creation of custom profiles, which can be tailored to meet specific requirements, such as strength, durability, and aesthetics. Additionally, aluminum extrusions are often more cost-effective than other manufacturing methods, making them an attractive option for businesses looking to rreduce costs without compromising on quality.

Precision Solutions for Custom Needs

Aluminum extrusion services provide precision solutions for custom needs, allowing businesses to create complex shapes and designs that meet their specific requirements. This is achieved through the use of advanced technology, including computer-aided design (CAD) software and precision machining equipment. By leveraging these tools, manufacturers can create custom profiles with tight tolerances, ensuring a precise fit and finish.

Custom Aluminum Extrusions for Various Industries

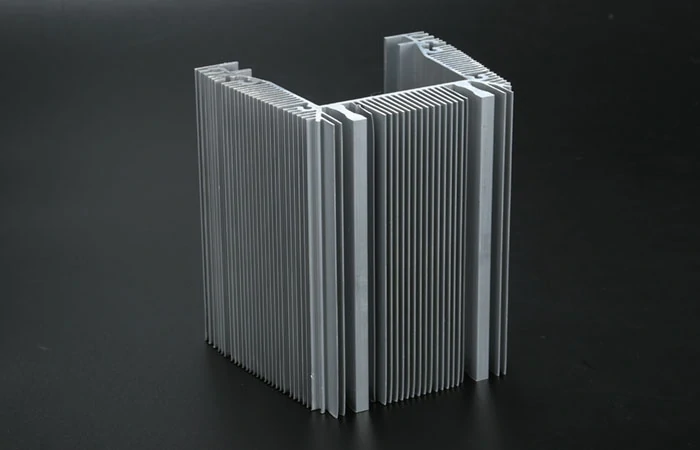

Aluminum extrusions are used in a wide range of industries, including architecture, industrial equipment, and consumer products. In the architectural industry, aluminum extrusions are used to create window frames, door handles, and other decorative features. In the industrial equipment industry, they are used to create machinery parts, conveyor systems, and other components that require strength, durability, and corrosion resistance.

The Importance of Quality and Precision

Quality and precision are essential when it comes to aluminum extrusion services. Manufacturers must adhere to strict quality control measures to ensure that their products meet the required standards. This includes using high-quality materials, maintaining precise tolerances, and conducting regular inspections to ensure that products are free from defects.

Working with a Reputable Aluminum Extrusion Manufacturer

When working with an aluminum extrusion manufacturer, it is essential to choose a reputable company with a proven track record of delivering high-quality products. This includes researching the company’s experience, capabilities, and customer reviews. By partnering with a reliable manufacturer, businesses can ensure that their custom aluminum extrusions meet their specific needs and are delivered on time.

Meeting Custom Requirements with Advanced Technology

Aluminum extrusion manufacturers use advanced technology, including CAD software and precision machining equipment, to create custom profiles that meet specific requirements. This technology allows manufacturers to create complex shapes and designs with tight tolerances, ensuring a precise fit and finish. By leveraging these tools, manufacturers can meet the custom needs of their clients, delivering high-quality products that exceed expectations.

Conclusion

In conclusion, aluminum extrusion services provide precision solutions for custom needs, offering a versatile and cost-effective way to create complex shapes and designs for a wide range of applications. By partnering with a reputable manufacturer and leveraging advanced technology, businesses can create custom aluminum extrusions that meet their specific requirements, ensuring a precise fit and finish. Whether you are working on an architectural feature, industrial equipment, or consumer product, aluminum extrusion services can help you achieve your goals and bring your vision to life.