Dies are specialized tools used in manufacturing to cut, shape, and form materials into desired shapes and sizes. There are various types of dies, each designed for specific applications and industries. Understanding the different types of dies and their role in manufacturing is crucial for producing high-quality products efficiently and effectively. In this article, we will explore the different types of dies and their applications in various industries.

Blanking Dies

Blanking dies are used to cut out flat shapes from sheet metal or other materials. They are commonly used in the production of parts such as gears, washers, and other flat components. Blanking dies are designed to produce precise cuts and are often used in high-volume production runs. They are typically made from high-strength steel and are designed to withstand the rigors of repeated use.

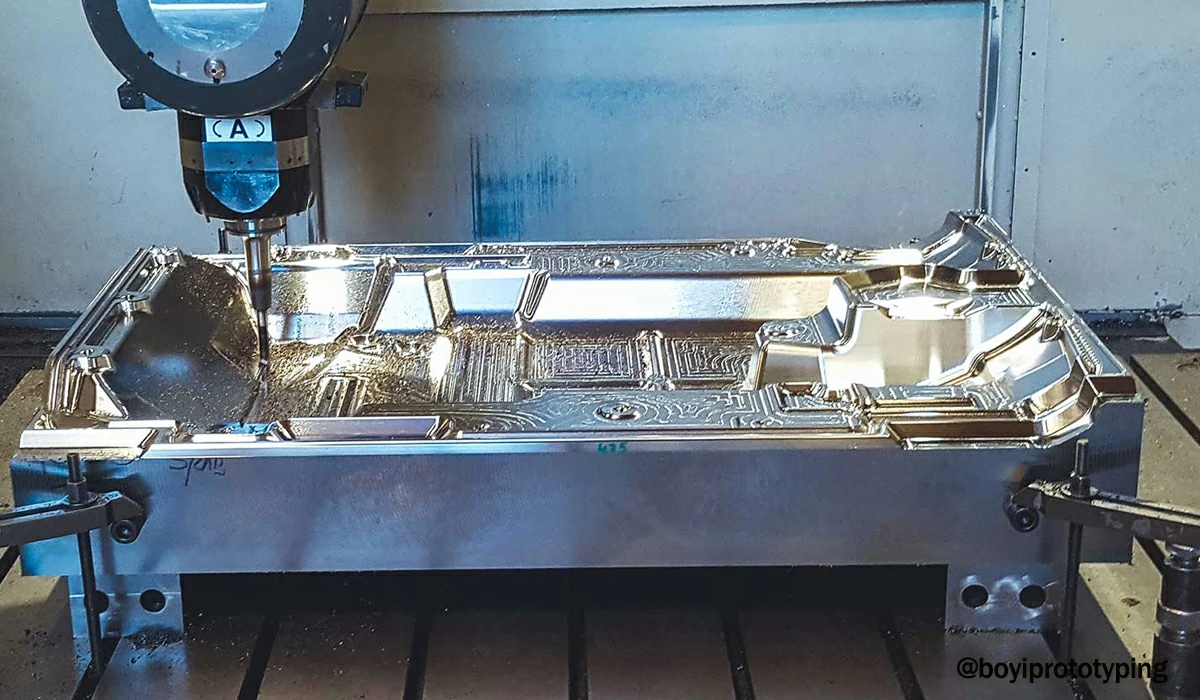

Forming Dies

Forming die manufacturing are used to shape and form materials into complex shapes and designs. They are commonly used in the production of parts such as car body panels, aircraft components, and other complex shapes. Forming dies are designed to produce precise shapes and are often used in conjunction with other manufacturing processes such as stamping and pressing.

Drawing Dies

Drawing dies are used to shape and form materials into cylindrical or tubular shapes. They are commonly used in the production of parts such as pipes, tubes, and other hollow components. Drawing dies are designed to produce precise shapes and are often used in conjunction with other manufacturing processes such as spinning and ironing.

Punching Dies

Punching dies are used to create holes in materials such as sheet metal, plastic, and other materials. They are commonly used in the production of parts such as gears, bearings, and other components that require precise hole placement. Punching dies are designed to produce precise holes and are often used in high-volume production runs.

Bending Dies

Bending dies are used to bend and shape materials into complex shapes and designs. They are commonly used in the production of parts such as car body panels, aircraft components, and other complex shapes. Bending dies are designed to produce precise shapes and are often used in conjunction with other manufacturing processes such as forming and pressing.

Progressive Dies

Progressive dies are used to perform multiple operations on a material in a single pass. They are commonly used in the production of parts such as car body panels, aircraft components, and other complex shapes. Progressive dies are designed to produce precise shapes and are often used in high-volume production runs.

Transfer Dies

Transfer dies are used to transfer materials from one die to another during the manufacturing process. They are commonly used in the production of parts such as car body panels, aircraft components, and other complex shapes. Transfer dies are designed to produce precise shapes and are often used in conjunction with other manufacturing processes such as forming and pressing.

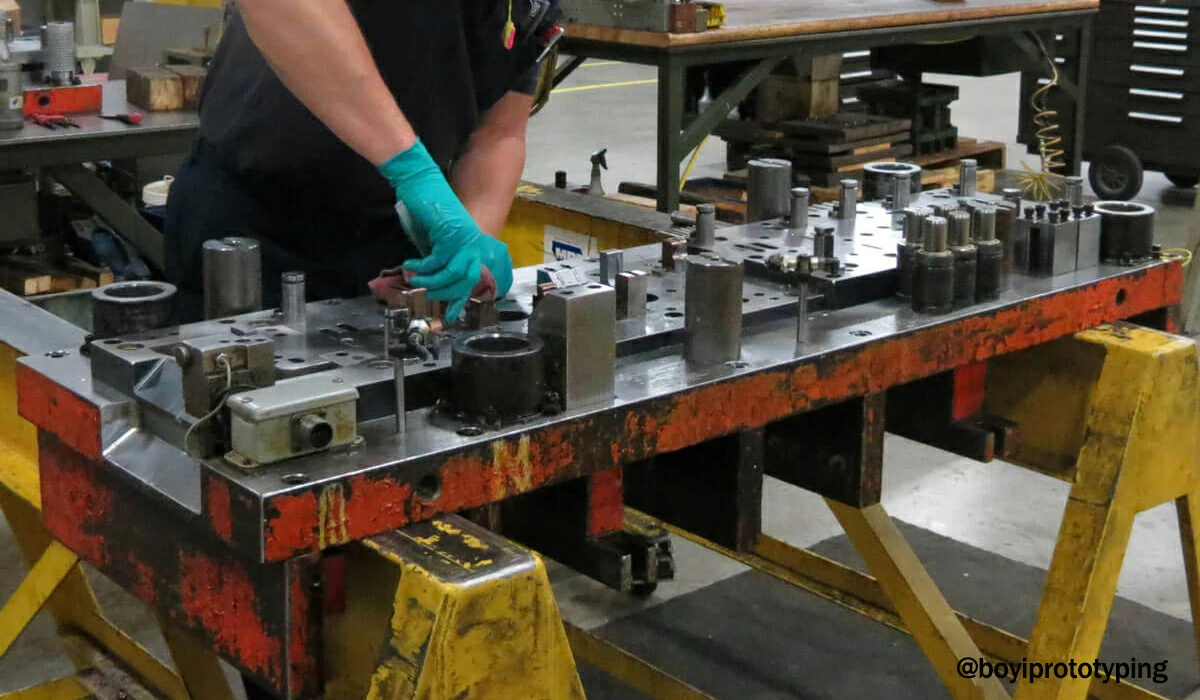

Die Materials and Construction

Dies are typically made from high-strength steel, aluminum, or other materials. The choice of material depends on the application, the type of material being formed, and the desired lifespan of the die. Dies are constructed using various techniques such as machining, casting, and forging. The construction of the die is critical to its performance and lifespan.

Conclusion

In conclusion, understanding the different types of dies and their role in manufacturing is crucial for producing high-quality products efficiently and effectively. Each type of die is designed for specific applications and industries, and selecting the right die for the job is critical to achieving precise shapes and designs. By understanding the different types of dies and their applications, manufacturers can improve their production processes and produce high-quality products.