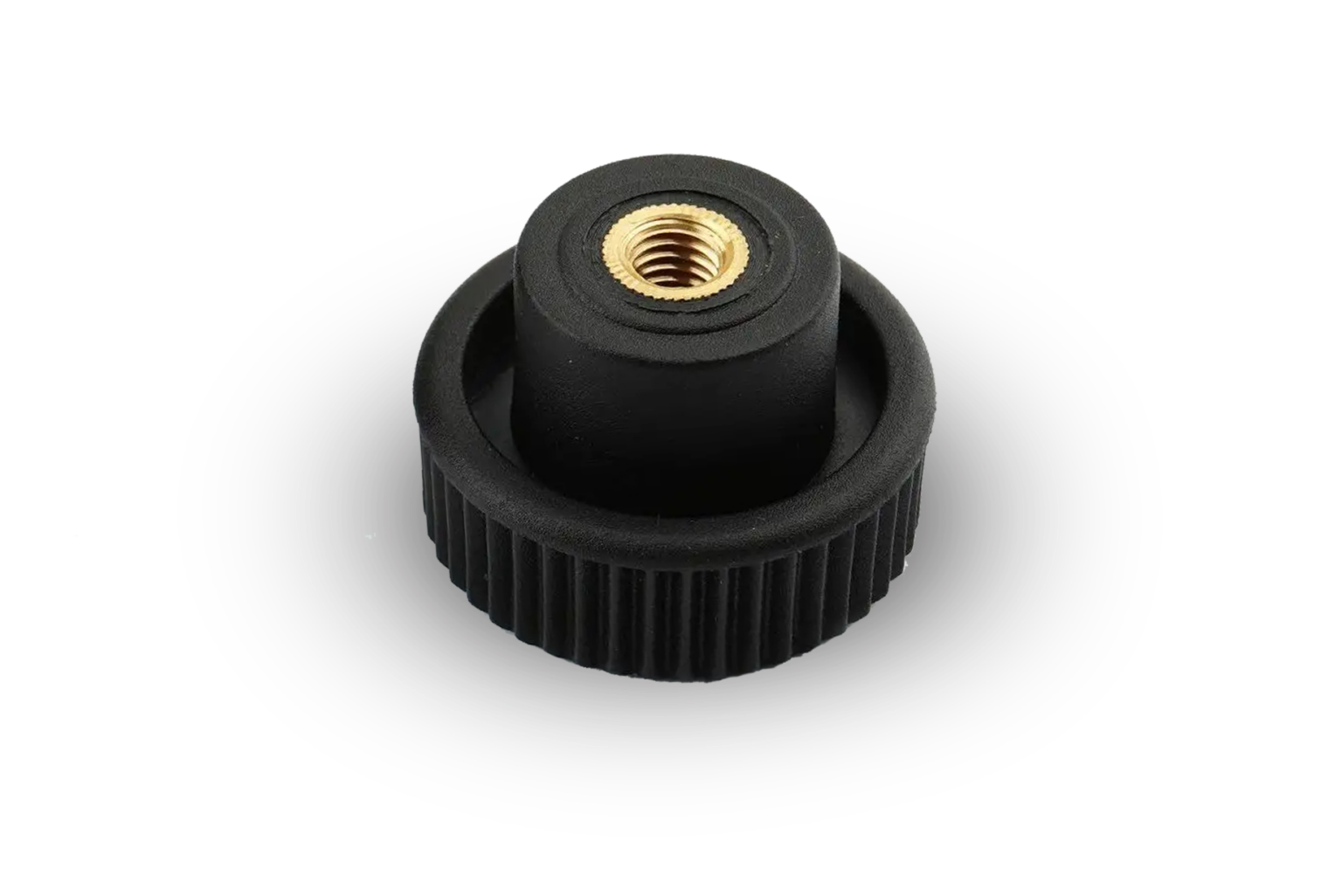

Insert molding services have become a popular choice for manufacturers looking to produce parts with improved strength and reliability. This process involves the integration of multiple components into a single part, eliminating the need for secondary operations and reducing production costs. In this article, we will explore the importance of insert molding services in improving strength and reliability, highlighting their benefits in terms of mechanical properties, durability, and performance.

Improving Mechanical Properties through Insert Molding

insert molding services offer a significant improvement in mechanical properties, such as tensile strength, flexural strength, and impact resistance. By integrating multiple components into a single part, manufacturers can create parts with improved load-bearing capacity and resistance to deformation. This is particularly important in industries where parts are subject to high stresses and strains, such as aerospace and automotive.

Enhancing Durability through Insert Molding

Insert molding services also offer improved durability and resistance to wear and tear. By integrating multiple components into a single part, manufacturers can create parts with improved surface finish and reduced risk of corrosion. This is particularly important in industries where parts are exposed to harsh environments, such as chemicals and extreme temperatures.

Improving Performance through Insert Molding

Insert molding services can also improve the performance of parts by reducing the risk of failure and improving overall reliability. By integrating multiple components into a single part, manufacturers can create parts with improved thermal conductivity, electrical conductivity, and other critical properties. This is particularly important in industries where parts are critical to the overall performance of a system, such as electronics and medical devices.

Reducing Material Costs through Insert Molding

Insert molding services can also help reduce material costs by minimizing waste and optimizing material usage. By integrating multiple components into a single part, manufacturers can reduce the amount of material required and minimize the risk of material defects. This is particularly important in industries where material costs are high, such as aerospace and automotive.

Improving Manufacturing Efficiency through Insert Molding

Insert molding services can also improve manufacturing efficiency by reducing the number of secondary operations required. By integrating multiple components into a single part, manufacturers can eliminate the need for assembly, welding, and other secondary operations. This can help reduce labor costs, minimize the risk of errors and defects, and improve overall manufacturing efficiency.

Conclusion

In conclusion, insert molding services offer numerous benefits in terms of strength, reliability, and performance. By integrating multiple components into a single part, manufacturers can create parts with improved mechanical properties, durability, and performance. As the demand for high-performance parts continues to grow, the importance of insert molding services is likely to increase, driving innovation and growth across industries.