Sodium silicate, commonly known as water glass, is a versatile compound used in various industries. It plays a crucial role in applications such as detergents, adhesives, and construction materials. The production of sodium silicate involves a chemical reaction between silica and sodium carbonate. This process can be complex and requires precise control over various parameters to ensure product quality and efficiency.

Importance of Automation

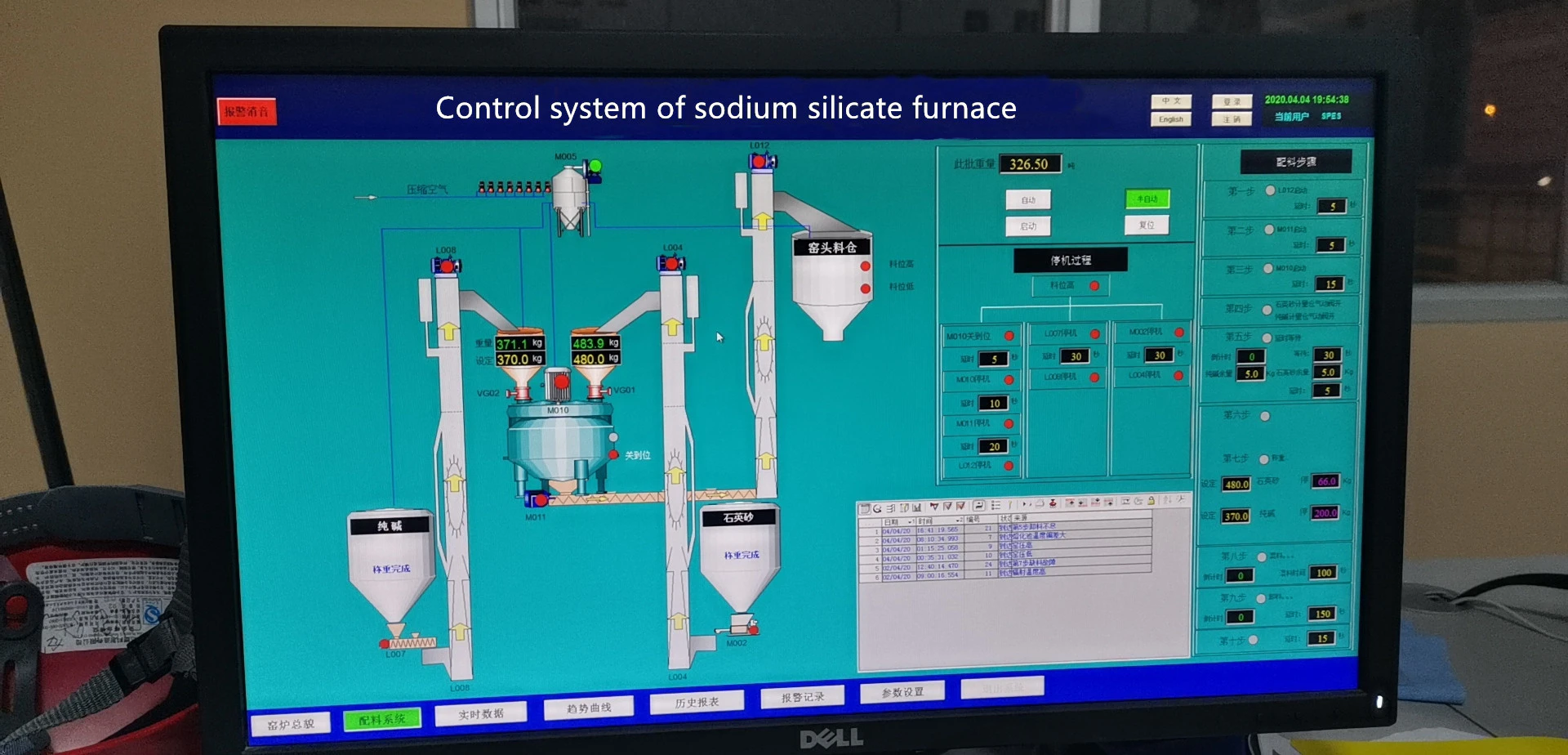

Automation has become increasingly important in the production of sodium silicate plant. By integrating automated systems, manufacturers can enhance productivity, reduce human error, and improve safety. Automation allows for continuous monitoring and control of the production process, ensuring that the right conditions are maintained throughout.

Enhanced Efficiency

One of the primary benefits of automation in sodium silicate production is enhanced efficiency. Automated systems can operate continuously without the need for breaks, leading to increased output. This continuous operation helps to meet the growing demand for sodium silicate in various industries.

Quality Control

Automation plays a vital role in maintaining quality control during the production of sodium silicate. Automated systems can monitor critical parameters such as temperature, pressure, and chemical concentrations in real time. This continuous monitoring allows for immediate adjustments to be made, ensuring that the final product meets the required specifications.

Reduction of Human Error

Human error is a significant risk factor in any manufacturing process. Automation helps to minimize this risk by reducing the reliance on manual labor. Automated systems can perform repetitive tasks with precision, reducing the likelihood of mistakes that can lead to production delays or quality issues.

Safety Improvements

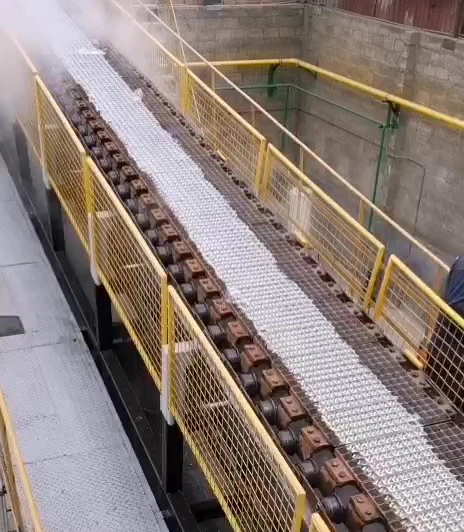

The production of sodium silicate involves handling hazardous materials and high temperatures. Automation can improve safety by minimizing human exposure to these risks. Automated systems can handle dangerous tasks, such as mixing chemicals or operating high-temperature equipment, reducing the potential for accidents and injuries.

Cost-Effectiveness

While the initial investment in automation technology can be significant, the long-term cost savings can be substantial. Automated systems can reduce labor costs, increase production efficiency, and minimize waste. These factors contribute to a more cost-effective production process, making it an attractive option for manufacturers.

Integration of Advanced Technologies

The integration of advanced technologies, such as artificial intelligence and machine learning, is transforming the automation landscape in sodium silicate production. These technologies can analyze data from the production process to identify trends and optimize operations. By leveraging these insights, manufacturers can further enhance efficiency and product quality.

Scalability of Production

Automation allows for greater scalability in sodium silicate production. As demand fluctuates, automated systems can be adjusted to increase or decrease production levels without significant downtime. This flexibility is essential for manufacturers looking to respond quickly to market changes.

Environmental Considerations

Automated production lines can also contribute to more environmentally friendly practices. By optimizing resource use and minimizing waste, automation can help reduce the environmental impact of sodium silicate production. Additionally, automated systems can monitor emissions and ensure compliance with environmental regulations.

Conclusion

In conclusion, automation plays a crucial role in the production of sodium silicate. It enhances efficiency, improves quality control, reduces human error, and increases safety. As manufacturers continue to adopt automated systems, the benefits will become even more pronounced. The future of sodium silicate production lies in the integration of advanced technologies that will further optimize the process and meet the demands of various industries.